Co-ordinate Measuring Machine (CMM)

CMM is non portable machine/device used for measurement of geometrical characteristics of 3D (three dimensional) object with use of digital interface. It measures length, height, width, diameter, angles, and form of surface and profile of any object by use of coordinate points. It can also measure centre distance between two circle, curvature, curvature radius, corner angle of object, hole size and hole height. All mathematical tool to measure is in built in microprocessor. CMM works on the principal to take continuously many coordinates points (by use of probe or laser) and these points used to forms the characteristics of surface in CAD system. CMM has been used in workshops, manufacturing industry, production houses and assembly etc. It is not widely use in general purpose. CMM machine measures the object dimension and takes readings in 6 degree of freedom as 3 degree of freedom is provided by main structure and three degree of freedom is provided by probe. This machine is either controlled by manually (use of joystick) or it is computer controlled.

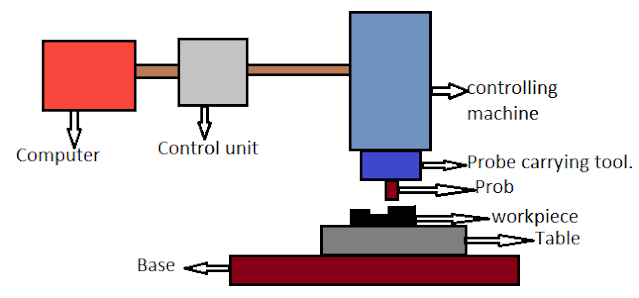

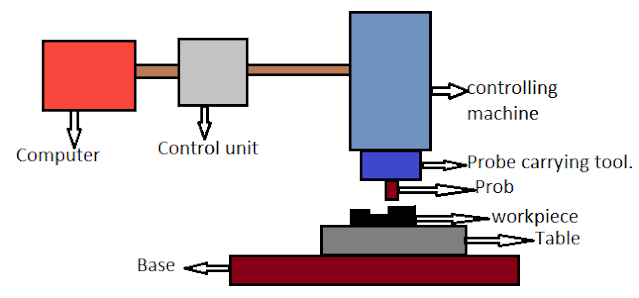

Component of CMM

In terms of basic construction of CMM machine, there are basically five components. These are probe system, main structure, interface& controller, CMM software, and computer.

|

Pic credit - Mechanicaleducation.com

Probe system Probe system consists of probe holder, sensing device and stylus. In general probe is combination of different sensing device , probe are two type .One is contact type and another is non-contact type. In the case of non-contact type laser beam is used to takes readings at different points. Non-contact type probe is more accurate and precise as compare to contact type because of stylus presence in non-contact type probe, size of may be compressed or expand due to load and thermal effect. In case of contact type, mechanical probe is used with the stylus. Stylus is component of mechanical probe system which touch the surface of object and provide input to probe. When stylus touch the surface of object sensor sense it and beep sound alarming. Probe holder holds the probe system and connect with main structure of machine. Probe have 3 degree of freedom.

|

Main structure

Machine structure consists of different arms which have servomotor and servomechanism internally which provides movement to structure in x, y, and z directions. So main structure have three degree of motions. Main structure controlled by controller. Different design of main structure available in market like gantry type main structure, vertical type(column type) main structure, horizontal type main structure, motorized type main structure, bridge type & cantilever type main structure.

Interface and Controller

Interface provides data and readings to user in digital format . Controller is microprocessor unit which well programmed and designed to drive main structure, and it can learn self, if any person provides manual movement to probe.

Software and Hardware

CMM may be controlled by computer system of may not be. But use of hardware and software increase flexibility and decision-making capacity and reduces chances of errors. However initial capital investment is more to installed this system. It enhance operation ability and efficiency. It provides ease data regarding to manufacturing and assembly of parts.

written by Shakti Dhar Rai.

( Mechanical Engineer )

For More Details

No comments:

Post a Comment